Industrial Metal Sawing - BAHCO Bandsaw Blades - Welded to Length

Quality. Consistency. Bahco strives to maintain the quality of its products and deliver cost per cut savings

consistently. We take a Rapid Continuous Improvement (RCI) approach to our production processes,

which reflects in the quality and performance of our product.

Precision tools you can rely on:

Quality is our number one priority and we also believe that a key factor in both production cutting

and general purpose cutting is product consistency. We take a Rapid Continuous Improvement (RCI)

approach to our production processes, which reflects in the quality and performance of our product.

We strive to continually improve our quality management system focusing on customers’ needs and

satisfaction

Precision tools you can rely on:

Quality is our number one priority and we also believe that a key factor in both production cutting

and general purpose cutting is product consistency. We take a Rapid Continuous Improvement (RCI)

approach to our production processes, which reflects in the quality and performance of our product.

We strive to continually improve our quality management system focusing on customers’ needs and

satisfaction

|

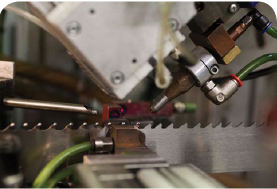

Tooth Forming High technology milling and grinding processes are used for precision tooth forming, enabling the production of sharper and stronger teeth. |

| Carbide Fusion Welding • High consistancy in carbide tip positioning • Stong bonding elimnates tooth strippage. All finished products are deliveried to our highly automated distribution centers. |

|

|

Setting |

3860 Multi-Chip Re-Saw Carbide Tipped bandsaw blade Weld to Length

CODE: 3860_Multi-Chip

Price: $0.00

3851 - Cobra, Flexible solution for cutting from general purpose to production

CODE: 3851

Price: $0.00